GRP GRATINGS

Real Safety Contact Info:

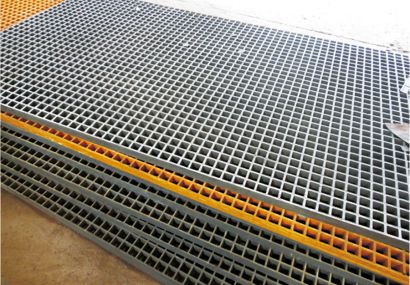

GRP molded fiberglass gratings

GRP molded gratings are lightweight and strong, and an ideal alternative to conventional steel grates.

GRP/FRP gratings offer superior load bearing, and are ideal in industrial and commercial settings where there may also be hazards such as liquids, oils, or debris on the surface, which can cause slips and falls.

Our composite gratings can be quickly installed over existing surfaces and are easy to clean and maintain.

Our gratings are widely used in various industries such as chemical plants, oil rigs, water treatment plants, construction sites and other industrial settings where safety is a top priority.

Real Safety fiberglass GRP gratings are the only ones on the market to be both certified and produced in the EU.

What are the benefits?

Real Safety GRP gratings provide several benefits, including:

- Cost effective – our grating only weigh about 1/3 of a steel grate, making them a cost-effective long-term investment

- Corrosion resistant – Our fiberglass composite grating lasts much longer than steel grates (no corrosion), making them suitable for use in environments where corrosion is a concern.

- Enhance safety – Installing our non-slip grp grating ensures that workers can safely walk on it even in wet and slippery conditions.

- Durability – Our GRP gratings are highly durable and can withstand heavy loads, extreme weather conditions, and exposure to chemicals and UV radiation.

- An ergonomic solution – Molded fiberglass gratings are comfortable to stand on and therefore an ideal grating for i.e. walkways.

A well designed fiberglass composite system like Real Safety Composite gratings is needed for flooring, walkway and decking areas in corrosive environments for superior load bearing and corrosion resistance. This is achieved by using good quality grade resins with UV inhibitors and other additives with sufficient glass fibre reinforcement.

Check out our FAQs, where you can find answers to most questions. If you can’t find the answer you’re looking for, get in touch.

Visit our Youtube Channel to view product installation guides.

As strong as conventional steel grates

Low weight – about 1/3 of a steel grate

Cost effective

Chemical-resistant and durable GRP

Easy to cut and install

GRP/ FRP gratings can be used in a variety of settings where superior load bearing, resistance to corrosion and the structural strength of the grating is of utmost importance.

Our gratings are a cost-effective solution and the ideal replacement to conventional steel grates.

- Construction sites

- Chemical plants

- Wastewater treatment plants

- Commercial and industrial settings

- Marine environment

- Walkways, flooring and platforms

- Staircases and step treads

- Foot bridges etc.

According to the Occupational Safety and Health Administration (OSHA), falls are one of the leading causes of injuries and fatalities specifically in the construction industry. In 2020, there were 401 fatalities in the construction industry, with falls being the leading cause of death.

A significant number of falls in the construction industry occur on walkways, stairways and ladders. OSHA added that about 20% of all fall-related injuries and fatalities involve ladders, and about 10% involve walkways and stairways. The consequences specifically in industrial and construction settings can be severe, both in terms of human cost and financial impact – including:

- Injuries and fatalities

- Lawsuits

- OSHA fines

- Damage reputation

KEY BENEFITS

Our fiberglass gratings are an ideal alternative to steel grates especially in construction for several reasons, including:

- Strength-wise they can be compared 1:1 with steel grate at the same height

- GRP gratings are extremely light. In fact they only weigh about ⅓ of a steel grate

- Slip safe even when wet from e.g. water, oil, or similar

- Installation around piping, tanks and other obstacles is much simpler with molded grating

- Panel sizes can be cut and fitted on site

- The chemical resistance of grating is superior and well suited for forklift traffic

- Designed for a max deflection of SPAN/100

- They are comfortable to stand on and therefore an ideal grating for i.e walkways

- These gratings do not corrode, are chemical-resistant and durable

- The lifetime of these non slip fiberglass grating is much stronger than a steel grate (no corrosion)

Frequently Asked Questions

If you can’t find the answer you are looking for here, please contact us.

Please view our installation and cutting guide for Grating here.

Cutting your grating is simple and similar to working with wood, with some slight differences. However, the solution will usually be delivered to size.

Regular cleaning will keep your grating product free of debris and looking new. Products are easily cleaned by high-pressure water or steam – or just a normal broom. Do not use steel brushes or chemical cleaners on the surface.

All our grating solutions come with a minimum ten year guarantee.

It depends on the size of the project and delivery costs. Contact us today! We would be more than happy to quote a price for you.

GRP grating can be considered a sustainable option for several reasons:

- Long lifespan: GRP grating has a long lifespan and require minimal maintenance, which reduces the need for frequent replacement and repairs

- Low energy consumption: The production of the GRP grating requires less energy compared to other materials such as steel and concrete – resulting in a lower carbon footprint.

- Lightweight: GRP materials are lightweight, making them easier to transport and install. That reduces fuel consumption and associated greenhouse gas emissions.

- Chemical resistance: GRP materials are resistant to corrosion and chemical degradation, reducing the need for chemical treatments or coatings, which can have negative environmental impacts.

Gratings are an ideal alternative for steel grates in a variety of settings. They are strong, lightweight and cost-effective over the lifespan of the project.

View our Fiberglass-Gratings-Datasheet for more technical details.

Fiberglass Molded Gratings are produced by wet moulding and hot curing in a heated mould. The reinforcement consists of continuous fibreglassrovings in alternating layers, so the loads are distributed evenly in all directions.

Regularly Molded Fiberglass Gratings have a polyester resin matrix and glass content is approximately 35%. The glass fibers provide strength and stiffness to the composite material making it durable and long lasting.

Our anti slip frp fiberglass gratings are available in three types of surface such as:

Grit Top, Concave Top, and Closed Grit Top.

We offer GRP gratings in standard grey (RAL 7004) or any other colour combination.

Choosing the right grating solution involves considering several factors – including:

- Intended application

- Identifying the environment and requirement to i.e. chemical substances

- Cost and installation

- Load bearing strength of the area in question

- Choosing the right surface grit

- Maintenance requirements

- Determining safety and anti-slip requirements

- Deflection span

- Ergonomics of the product

By considering these steps, you can select light-weight, strong, non-corrosive grates that are appropriate for your specific application – providing a durable and cost-effective solution.

We offer our clients a personal consultancy approach to gain an in-depth understanding of the industry they serve and the challenges they are facing, so we can provide them with the best solutions.

If you have a project that would benefit from having high-quality grating ínstalled, please give us a call.

Other GRP Composite solutions

Stair Treads

Our GRP fiberglass stair tread gratings are lightweight – and strong, and an ideal alternative to conventional steel grating, concrete etc. They offer superior load bearing and are ideal in industrial and commercial settings.

Read more about our stair tread solution

GRP Pultruded Profiles

Whereas traditional construction materials like concrete, steel, aluminium and timber have only one strength, FRP/GRP construction pultruded profiles have several advantages. That makes using them a particularly cost-effective solution.

Read more about our Pultruded profiles.

Stairway and ladder system

Make your platforms, ladders and stairs ergonomic, safe to work on. Our GRP stairway and ladder systems can be developed and installed to just about any size and specification. With or without linking elements.

Read more about our Stairway and ladder system