GRP PROFILES

Real Safety Contact Info:

Pultruded GRP/FRP Profiles

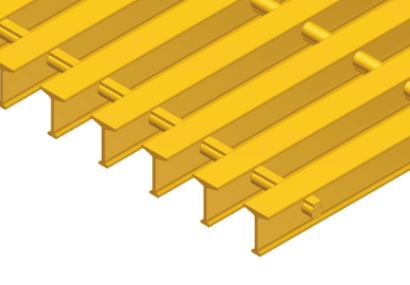

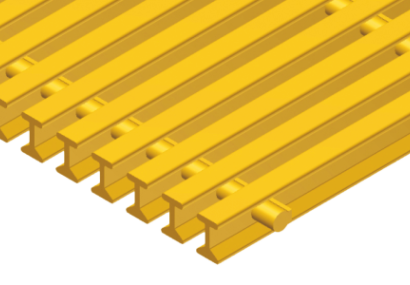

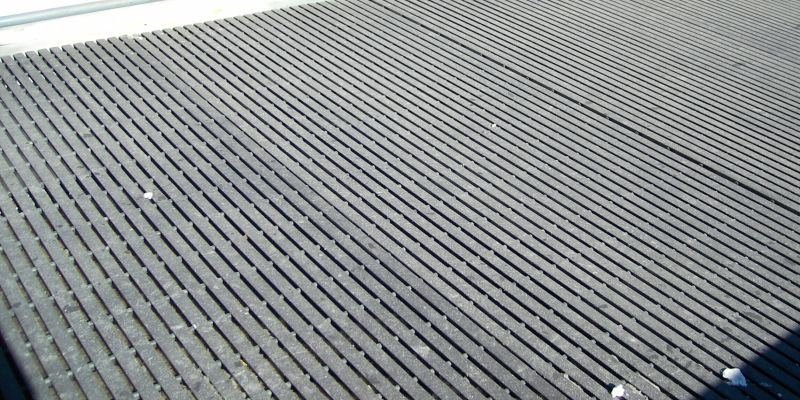

Real Safety GRP/FRP pultruded fiberglass gratings are known for their high strength, corrosion resistance and durability in the most difficult environments – whilst adhering to the highest international standards.

They are therefore ideal solutions for a wide range of applications in for example construction and heavy industry sectors.

You get a reliable solution for several years as they are assembled from interlocking pultruded profiles. That outperforms the traditional materials they replace – typically steel. Being lightweight, easy to put together and install, good performance and cost effectiveness makes pultruded gratings a better choice than steel.

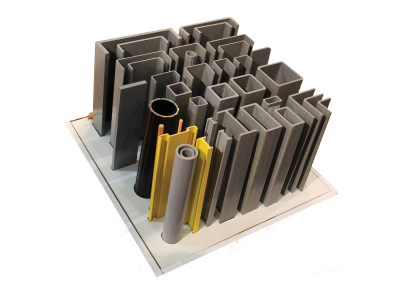

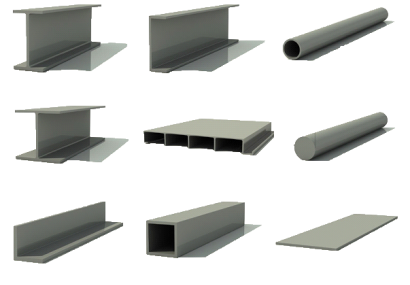

We offer a wide range of grp pultruded construction profiles, including I Beams, U Channel, C Channel, Beams, Rods, Tubes etc.

What are the benefits?

Our GRP/FRP pultruded structural profiles offer many advantages over traditional materials such as wood, steel or concrete, including:

- More lightweight than traditional building materials, making them easy to handle, transport and install

- A high strength-to-weight ratio and extremely durable – and ideal for use in structural applications

- Performs structurally better than molded grating with a maximum deflection limited to SPAN / 200 (same limit as steel grating)

- Minimal maintenance cost, which helps to reduce long-term costs and downtime

- Unaffected by both water and corrosion

- Chemical resistant beams and profiles

- All of our pultruded constructional materials are manufactured in accordance with CTI 137 standard.

View our Water Desalination case study, where we successfully supplied a range of profile materials for a major construction project in Saudi Arabia.

Need some help or got a question? Check out our FAQs, where you’ll find answers to most questions. If you still can’t find the answer you’re looking for, please Contact us!

Visit our Youtube Channel to view product installation guides.

High strength

Fire retardant

Corrosion resistant

Lightweight

Non-conductive

GRP or FRP structural pultruded profiles are manufactured by combining a resin matrix with a fibre reinforcement. This is formed and cured in a continuous process creating a product of extraordinary strength and resilience. GRP Structural Pultruded Profiles provide a variety of benefits and mechanical properties matching or exceeding steel equivalents.

Whereas traditional construction materials like concrete, steel, aluminum and timber have only one strength, our GRP/FRP structural profiles have several advantages. That makes using them a particularly cost-effective solution.

A wide range of structural profiles are available including: U Channel, I – Beam, Tube, Box, Angle, Rod and Hand Rail.

GRP/FRP pultruded profiles are commonly used in a variety of projects and industries due to their excellent mechanical properties, durability, and resistance to environmental factors.

- Construction

- Industrial

- Chemical processing

- Transportation

- Marine

- Oil and Gas

Accidents specifically on construction sites can occur due to a variety of factors, such as human error, equipment failure, or unforeseen events. Furthermore, the use of certain construction materials, such as steel and concrete can increase the risk of accidents and injuries on job sites due to their weight and handling requirements.

The use of lightweight and easy-to-handle materials such as FRP pultruded profiles can help reduce the risk of accidents and injuries, but it is important to follow all necessary safety procedures and guidelines regardless of the materials used. Construction companies and other organizations may be held liable in the event of equipment failure: example workers can be crushed by heavy steel objects – this is why FRP profiles are the best alternative solutions because they are lightweight. Consequences may include:

- Legal penalties

- Regulatory Fines and Penalties

- Damage Reputation

KEY BENEFITS

Our GRP/ FRP profiles are an ideal alternative to steel grates especially in construction for several reasons, including:

- Chemical resistant and unaffected by water and corrosion

- High strength 1:1 steel equivalent

- Low weight – 1/3 of steel

- Low installation costs. Structural profiles are lightweight – reducing the need for heavy equipment

- No maintenance

- Low environmental impact

- Maximum deflection limited to SPAN / 200 (the same limit as steel grating)

- The profiles are comfortable to stand on

- Fiberglass profiles last longer than steel grates (no corrosion)

- No need to use torches during installation

- Non-conductive and flame retardant, making them ideal for electrical and other applications where safety is a concern

- Cost effective

For other mechanical data, please contact us, we will be more than happy to help you.

Frequently Asked Questions

If you can’t find the answer you are looking for here, please contact us.

Real Safety pultruded profile gratings are easy to install using standard tools and techniques. Use our accessories and fixing sets – specifically developed for this product.

View our Mounting Kits and Accessories data sheet for more information.

Fixing sets:

Easy to assemble without any special tools.

A pultruded fiberglass angle can be used as a frame for all fiberglass gratings.

Stainless steel fixing sets can be used for all standard fiberglass gratings and support constructions. To prevent fiberglass gratings against lifting and sliding away, each panel should be fixed on at least four points.

Regular cleaning will keep your grating product free of debris and looking new. Products are easily cleaned by high-pressure water or steam – or just a normal broom. Do not use steel brushes or chemical cleaners on the surface.

All our grating solutions come with a minimum ten year guarantee.

It depends on the project and delivery costs. Contact us today! We would be more than happy to quote a price for you.

According the market research report by Mordor Intelligence, increasing demand for lightweight, durable, corrosion-resistant materials in construction applications is driving growth of the pultrusion market, this is simple because GRP/ FRP composite materials can offer a more significant value over traditional materials such as steel and concrete in the construction bridges, and other structures.

The study also found that pultruded materials are more sustainable due to their longer lifespan and lower maintenance requirements.

FRP Pultruded profile grating can be considered a sustainable option for several reasons:

- Long lifespan: FRP grating has a long lifespan and require minimal maintenance, which reduces the need for frequent replacement and repairs

- Lightweight: Profiles are lightweight, making them easier to transport and install, which reduces the fuel consumption and associated greenhouse gas emissions

- Chemical resistance: FRP materials are resistant to corrosion and chemical degradation, reducing the need for chemical treatments or coatings, which can have negative environmental impacts.

Do you need help finding the best solution? You are always welcome to contact us.

Gratings are an ideal alternative for steel grates in a variety of settings. They are strong, lightweight and cost-effective over the lifespan of the project.

View our pultruded grating brochure for more technical details. FRP/GRP material fibre reinforced plastic/glass fibre reinforced plastic is a composite material made of a polymer matrix reinforced with fibers.

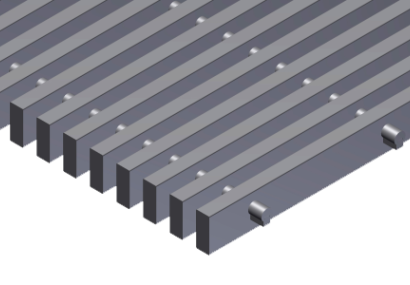

Pultrusion is the process of pulling fiberglass reinforcements such as mats and strands through a proprietary resin and heated die.

This production method is particularly suitable for tubes, profiles etc. reinforced with continuous fibers, involving pulling of impregnated fibers via preformers providing the form as, simultaneously, the plastic is hardened with heat (thermoset) or cooled until solid (thermoplast).

The result is a specific complex profile that can be cut to any length. This process offers speed and consistency, making it the best method for producing high-volume linear fiberglass products that require constant cross sections.

Unlike molded grating which has equal strength in both directions, Real Safety’s pultruded grating is stronger in the longitudinal direction as it is fabricated from bearing bars & interlocking rod and groove bar assemblies.

The resulting profiles are lightweight and resistant to a variety of environmental factors, including corrosion, UV radiation and chemicals.

All of our pultruded construction grp/frp profiles are manufactured in accordance with CTI 137 Standard.

Choosing the right GRP/FRP profiles for your construction projects will depend on several factors such as application, environment conditions, and load requirements. Key considerations include:

- Intended application

- Cost and installation

- Identifying the environment and requirement to i.e. chemical substances

- Load bearing strength of the area in question

- Maintenance requirements

- Determining safety requirements

- Ergonomics of the product

- Determining the overall lifecycle cost of the product

Working with a trusted supplier that can also help you ensure you choose the right profile for your project. We offer our clients a personal consultancy approach to gain an in-depth understanding of the industry they serve and the challenges they are facing, so we can provide them with the best solutions.

If you have a project that would benefit from having high-quality pultruded grating profiles ínstalled, please contact us, we would be happy to assist you.

Other anti-slip solutions

GRP Grating

GRP/FRP molded gratings are lightweight and strong, and an ideal alternative to conventional steel grates. The composite gratings can be quickly installed over existing surfaces and are easy to clean and maintain.

Read more about our GRP Grating

GRP Stair Treads

Our GRP/FRP fiberglass stair tread gratings are lightweight – and strong, and an ideal alternative to conventional steel grating, concrete etc. They offer superior load bearing and are ideal in industrial and commercial settings.

Read more about our stair tread solution

Stairway and ladder system

Make your platforms, ladders and stairs ergonomic, safe to work on. Our GRP stairway and ladder systems can be developed and installed to just about any size and specification. With or without linking elements.

Read more about our Stairway and ladder system