STEP NOSING

Real Safety Contact Info:

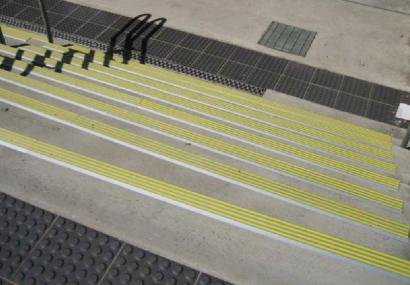

Anti-slip GRP Step Nosing for stairs

To prevent slips, trips and falls on stairs you need to identify and address the underlying causes.

Slippery stairs are the most common cause of stairway slip, trip and fall accidents. In fact, stairs that are exposed to oil, water, ice, grease or other chemicals, should always be anti-slip secured to prevent accidents and injuries.

This is why our anti-slip FRP step nosing for stairs is an essential safety solution. Stair nosing strips secure staircases exactly where the accident happens: on the edge of the step! Therefore, the friction area must always cover the ‘nose’ in order to work effectively. Real Safety step nosing also promotes awareness due to the increased visibility of the steps.

What are the benefits?

Step nosing benefits for industrial, commercial, and other settings include:

- Improved safety – By providing increased traction, grip and visibility on the staircase – reducing the risk of accidents and injuries happening.

- Increased durability – The durable, high-quality glass fiber can withstand heavy foot traffic and wear and tear and has a long lifespan – reducing the need for frequent repairs or replacements.

- Compliance with safety regulations – Prevents severe work-related incidents (LTI) by increasing traction and visibility on stairs – thereby avoiding potential fines or legal liabilities.

- Cost effective and efficient solution – quick and easy to install and no specialized equipment is required.

Our stair step nosing is designed for easy installation and mounting onto existing steps. This is easily done all year round regardless of weather conditions. Anti slip edges can be fitted onto stairs made from steel checker plates, steel grating, concrete and even wooden steps.

Need some help or got a question? Check out our FAQs, where you’ll find answers to most questions. If you still can’t find the answer you’re looking for, please Contact us!

Visit our YouTube Channel where you can subscribe and view product videos.

Corrosion/chemical resistant

10 year warranty

Add print, logo or pictograms

Anti-slip high-quality GRP

Choice of sizes and colours

Step nosing, also known as stair nosing, fits over all types of existing steps with ease and is used to cover the front edge of the step for safety purposes. It is installed on the edge of the step to provide increased visibility and traction. Our step nosing can be used in any industrial and commercial setting, where stairs are present and safety is a concern.

- Oil and gas industry

- Construction

- Energy

- Manufacturing

- Food and Pharma

- Transportation

- Marine Industry

- Private and public sectors

Real Safety´s GRP step nosing is an excellent anti slip solution on different types of surfaces such as steel, wooden and concrete steps, and benefits include:

- Steel surfaces – Our step nosing can be used on steel steps, platforms, and other steel surfaces to add slip resistance, durability, safety and visibility.

- Concrete surfaces – Concrete steps can be susceptible to cracking and erosion over time, but adding our FRP nosing can help protect them from further damage and extend their lifespan.

- Wood surfaces – Common issues with wooden surfaces – especially in damp environments, are mold and mildew growth. It can present a number of dangers, particularly if they are not properly maintained or are exposed to moisture or wear and tear.

GRP Step nosing offers several advantages over other materials. It is a versatile and cost-effective solution for adding safety and durability to steel steps. It is easy to clean and maintain, which makes it a great option for areas that require frequent cleaning. Visit our Youtube Channel to view our video guide.

Step nosing is an important feature on stairs because it serves several critical functions that help to improve safety and reduce the risk of accidents. Falls on slippery steps on stairs are a significant cause of accidents, injuries, and fatalities – both in public places and workplaces.

According to the National Safety Council (NSC), falls are the third leading cause of unintentional injury related deaths, with falls on stairs being a significant contributor to this statistic. In fact, slips, trips and falls are one of the most common causes of injury at work in the UK and globally – accounting for 40% of all reported major injuries in UK workplaces alone.

Slips, trips and falls cause workers to miss an average of 38 workdays per year. They also account for 36% of emergency room visits and 65% of lost workdays. It is therefore no surprise that safety must be prioritized.

Any organization can be held liable for injuries that occur in the workplace due to a lack of safety measures. The legal concept of “negligence” is applied in these situations. Staff or visitors injured on the premises, may choose to file a lawsuit against the company, which could have serious consequences financially and with HSA compliance. Furthermore, negative PR can also have an impact and lead to decreased customer loyalty and reduced revenue.

Therefore, to avoid liability for injuries in the workplace, companies must take steps to ensure that their workplace is safe and that they are in compliance with relevant safety regulations.

To prevent accidents on stairs, companies should take the following steps:

- Install anti-slip step nosing to provide extra grip, which is particularly important in areas with high foot traffic and where stairs are likely to be wet and slippery

- Keep stairs well-maintained: This may include repairing broken or worn down steps and providing handrails

- Provide proper lightning and increase the visibility of the steps and step edges to reduce the risk of tripping and falling

- Follow relevant safety regulations

By taking these steps, companies can help prevent falls on stairs in the workplace and promote a safer working environment for their employees.

KEY BENEFITS

FRP/GRP Step nosing is designed to improve safety. It is a perfect addition for all types of existing stairs and can be retro-fitted regardless of the surface base (steel checker plates, steel grating, concrete, wood etc.). Benefits include:

- Highly resistant to corrosion and does not rust, making it ideal for use in environments that are exposed to moisture, chemicals, or other corrosive substances.

- We have encapsulated sharp aluminum oxide grit into the surface of the glass fiber to provide the step grips with optimum friction

- GRP/FRP step nosing is much lighter than traditional materials such as metal or concrete, which makes it easier to handle during installation.

- It is significantly more durable and can withstand heavy foot traffic, impact and exposure to harsh environmental conditions such as moisture, chemicals, and UV radiation.

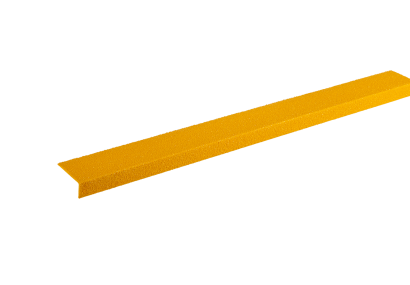

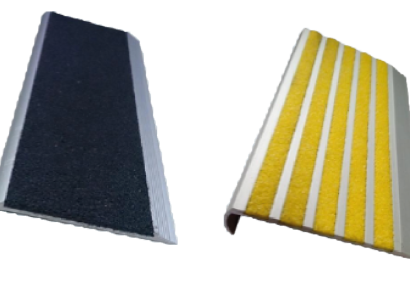

- Designed to enhance visual safety it is available in a solid colour or in a combination of two colours, typically black with a yellow “nose”, and in various widths and depths.

- We can also print text, pictograms or logos on the stair edge trim as desired.

- Quick and easy to install and retrofit on new or existing steps of stairs. No specialized equipment required.

- We offer a 10 year warranty and 360 service throughout the lifespan of the project.

- Non-conductive

- It can be molded to fit the shape of stairs and can be customized with a variety of colors and surface textures to provide slip-resistance

- Cost-effective alternative to traditional metal or concrete step nosing.

- Step covers are available in measurement from 450 – 3000 mm in length – and 75 mm depth.

We have delivered customized safety solutions for almost 20 years. We aim to reduce safety risks, using materials that minimize maintenance, enhance safety and promote sustainability.

Frequently Asked Questions

If you can´t find the answer you are looking for here, please contact us.

Please view our installation guide for Step Nosing here.

It is easy to install our step nosing solution.

Like our step covers, GRP step nosings are non-load bearing, and are pre-fabricated for quick and easy installation over existing surfaces including concrete, metal, aluminum, glassfiber, steel and composite grating, wood and tiles.

Depending on the base material of construction and surface to be covered, mechanical fasteners, urethane adhesive, PSA (pressure sensitive adhesive) and tack-welding can be used. Pre-drilled holes are available to aid in the process.

Regular cleaning will keep your step nosing free of debris and looking new. Most household methods can be used such as detergents and mild degreasers – provided that they are diluted with water and immediately hosed off with water.

For stubborn deposits, use a stiff bristle brush. High pressure cleaning may be used in an industrial environment.

A minimum of ten years.

It depends on the size of the step nosing needed – and delivery costs.

Contact us today! We would be more than happy to quote a price for you.

Step nosings can be considered environmentally friendly to some extent for several reasons:

- Long lifespan: FRP/GRP step nosings are designed to be durable and long-lasting – just like our step covers. That reduces the need for frequent replacement and helps minimize waste

- Low maintenance: Step nosings are resistant to water, chemicals, and other forms of wear and tear, which helps to reduce the need for frequent maintenance and repairs

- Recyclable: FRP/GRP is a recyclable material, which means that at the end of its lifespan, it can be recycled. That helps to reduce waste and preserve natural resources

- Energy efficient: The production of FRP is energy-efficient and does not produce harmful emissions or waste, which make it a more environmentally responsible choice compared to other materials.

Do you need help finding the best solution? You are always welcome to contact us.

They instantly improve safety wherever they are installed. The noses improve slip safety underfoot where it’s needed most: on the edge of the step – but step nosing also highlights the edge of the step to ensure visibility.

All our FRP/GRP products meet or exceed industry standards and regulations. View our FRP step nosing data sheet for more technical details.

Our step nosing is manufactured in FRP, a composite material that includes a mixture of fiberglass and resin. The specific types of fiberglass and resin used in our FRP/GRP step nosing, can vary depending on the application requirements and environment of the application. Step nosing is known for its durability, resistance to wear and tear, and low maintenance requirements, which makes it a popular choice for high traffic areas and industrial settings.

The slip resistance level of Real Safety’s solutions are all classified with the highest score of R13. DIN 51130 R-Value slipperiness classification ratings range from R9 – R13.

We offer the step nosings in a Yellow Ral 1003 or black colour.

Choosing the right step nosing depends on several factors. Key considerations when selecting step nosing include:

- The type of surfaces on which the stair nosing will be installed

- Identify the size and shape needed

- Assess of the traffic volume

- What anti-slip properties should it have

- Evaluate the environment

By following these steps, you can choose the right anti-slip step nosing ensuring maximum safety and reducing the risk of slips, trips, and falls.

If you are unsure about the best step nosing safety solution for your needs, please get in touch, we will be more than happy to help you.

Other anti-slip solutions

Anti-slip step cover

A quick and cost-effective way to upgrade slippery stairs is to use Real Safety’s anti slip step covers. Safety covers will slip proof the area – but more importantly, the anti slip steps will prevent accidents from happening in the first place! Read more about our step covers. step covers.

Anti-slip stair tread gratings

These are pre-formed, GRP stair treads that replace existing stair covers. They are as strong as steel grates, low weight and corrosion free. Furthermore, they are 100% maintenance free and therefore offer great ROI. Read about our stair tread

Anti-slip landing covers

Landing covers provide a slip-resistant surface on landing areas, such as the top or bottom of stairways and landings. They are made from high quality GRP – and come in four different colours and two surface grit options (extra coarse / coarse). Read about our landing covers